Incubator MG320S MAXI PRO

no.4 hatching baskets kit

| Eggs Capacity | Setter/Hatcher |

| Hen - Duck - Mallard | 320 |

| Pheasant | 357 |

| Red legs | 1070 |

| Partridge - Quail | 1340 |

| Turkey | 250 |

| Goose (specific tray) | 75 / 100 |

| Technical data | ||

| Power Supply | V/Hz | 220-230 / 50-60 |

| Power Consumption | Watt. | 250 |

| Sizes | mm | 560x820x730H |

| Net Weight | Kg | 40,5 |

The incubators mod. MAXI PRO have been recently conceived and manufactured to meet the needs of people interested in starting a professional incubation project, without high capital investment. They combine a good capacity for eggs with a set of innovative systems allowing the user to work safely, fully complying with needs of small breeding farms. Thanks to high-quality manufacturing materials, these incubators associate long duration with performance applicable to a professional machine.

Highly versatile thanks to universal metal setting trays and overlapping and movable hatching plastic baskets, providing for the simultaneous incubation of several species. Then, the user can perform weekly incubation cycle or apply the “completely full/completely empty” system.

• The structure consists of special walls made of prepainted galvanized sheet thermal panels, with 20-mm polystyrene insulation, ensuring perfect isolation and machine solidity (Ref. Mod. MG 320-540-1000).

• Daily turning of eggs is performed by proper high-quality geared motor which - thanks to constantly automated operation – helps proper embryo development, preventing dangerous adhesions to egg shells.

• The electronic control unit with backlit LCD allows managing – with a very easy usage – temperature, humidity and many other relevant parameters.

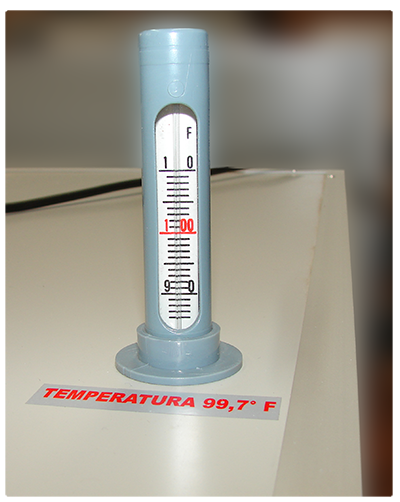

• Temperature is read through °F precision thermometer and a wet-bulb hygrometer provides for an accurate reading of humidity percentage inside the incubator.

• A port-hole on the door provides for a perfect view inside the incubator and the internal light allows an easy inspections of the eggs.

• The machines MG540-1000 are equipped with one self-cooling bearing professional fan and a special device to adjust ventilation intensity. The mod. MG320 is equipped with electronic fan. The suitable air exchange followed by carbon dioxide exhaustion is through proper ventilation holes.

• Humidification is performed through covered tank with constant level automatic water flow (automatic humidification is available upon request with digital adjustment and further reading through hygrostat).

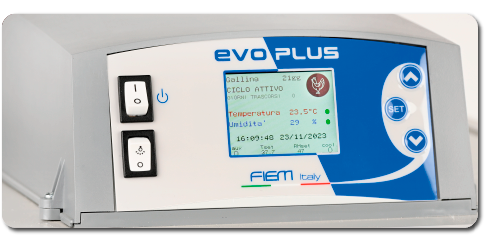

New “Evo Plus” Control Board

8 preset programs for each poultry species:

HEN, DUCK, GOOSE, QUAIL, PHEASANT, PARTRIDGE, TURKEY, GUINEA FOWL

CUSTOM program: for customizing incubation parameters

GERMINATION program: LED light on/off management timings for germination and plants growth

HATCHING program

- 4” TFT LCD color graphic display

- Extremely performing microprocessor for the highest accuracy in temperature and humidity management

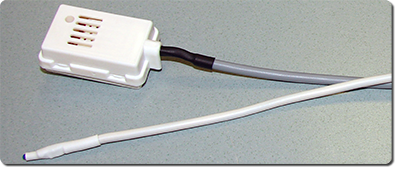

- New professional self-calibrating T/H sensor with top accuracy / temp. ± 0.1°C and humidity ±1.5%RH

- ON/OFF temperature management mode

- °C/°F immediate conversion setting

- Calendar : Incubation day counter and hatching cycle start warning

- Double incubation temperature program

- Temperature time bands program

- Egg turning program up to 4 intervals

- High temperature audible alarm

- Language setting: Italian/English

Optional function: Electric cooling (Clima Version)

OPTION: additional temperature sensor for external temperature display (room where the incubator is positioned)

OPTION: expansion for remote (plug-in WiFi module) viewing and control by a mobile phone

AUTOMATIC HUMIDITY (OPTION ON DEMAND)

- option 1 : NEW AUTOMATIC HUMIDIFICATION – By heating resistance: a constant & gentle automatic humidification system with digital adjustment by evaporation of heated water - available for more models

AUTOMATIC HUMIDITY BY HEATING RESISTANCE

|

DOUBLE T/H PROBE |

- option 2 : AUTOMATIC HUMIDITY BY ULTRASOUNDS Ultrasounds humidifier (on demand) |

|

|

|

|

| Thermo-hygrometer kit for temperature and humidity values reading. | ||

|

|

|

The safety of electric components fully complies with EEC standards and the control panel outside the incubator helps preventing any problem with electric components arising from humidity and condensate.